Sustainability, reuse of raw and secondary raw materials and innovation, namely, "circular economy"

Purchases and circular economy

The company operates on the purchasing front following two lines of activity:

- Purchase of hyper-pure raw materials – such as SHG zinc, Mozal aluminium, magnesium and copper – in the form of ingots that only require a product sheet and that are sent straight to production without any intermediate step of spectrochemical analysis

- Purchase of production waste and by-products from its customers or from third parties. This methodology fulfils the criteria of the circular economy, since it converts the commodities defined as “waste” by the standards into a finished product, avoiding onerous and harmful landfill sorting.

- The above-mentioned materials, whether they come from our customers or from third parties, are subject to several radiometric tests, sorting, and spectrochemical analysis using a specific analyser with 4 decimal places.

- In this context, S. Erasmo Zinkal is interested in offers concerning production scrap or first choice by-products such as skimmings, automotive moulds, scraps 1 (treated material free from impurities), scraps 2 with max 5% attachment (iron residues), zinc anodes, zinc turning, new zinc sheets.

Production scrap

SKIMMINGS

BEANS AND RUNNERS

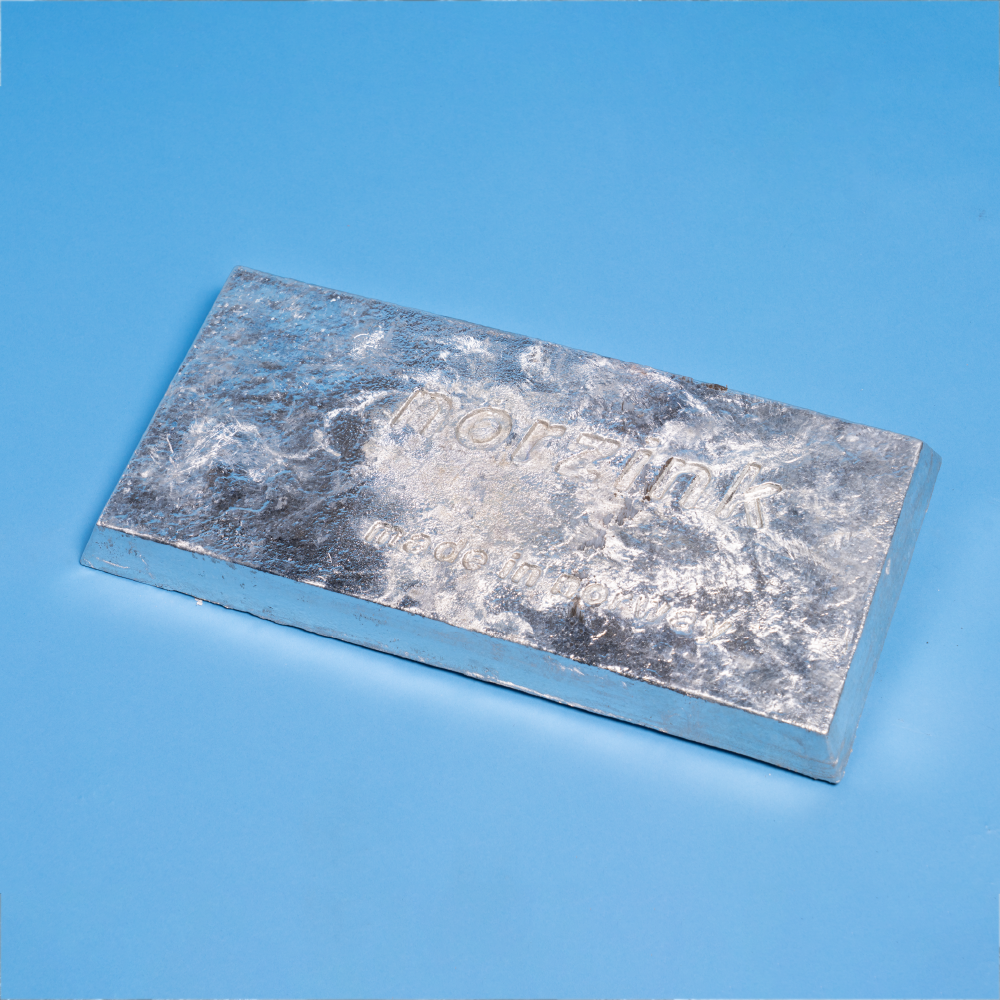

ANODES

Raw materials

ZINC INGOTS

ALUMINIUM INGOTS

HYPER-PURE MAGNESIUM INGOTS

Moulds, turnings, scraps

We purchase zamak moulds of any size, whether containing iron (max 5%) or not. The analyses of the material must be guaranteed by appropriate certificates.

We purchase zamak turnings both in bulk and in metal containers. The material must be free of oil and water, not oxidised, and free from contamination by other materials. The analyses of the material must be guaranteed by appropriate certificates.

We purchase scraps both in bulk and in metal containers. The material must be new, clean and free of any surface treatment, with max 5% (scraps 1) of iron, or without any kind of inserts, and not mixed with other types of scrap (scraps 2).

Skimmings, beans and runners, anodes

We purchase skimmings both in metal containers and in bulk. The material must be new and clean, without any inserts of iron or treated material. The analyses must comply with UNI EN 1774 standards. We purchase zamak scrap – beans and runners – that must be new, clean, without inserts and not mixed with other types of scrap. We purchase zinc anodes, with or without iron, both in metal containers and in bulk. The material must be accompanied by analyses to certify its quality and metallic content.

Zinc ingots

We purchase LME brand-registered SHG zinc (min 99.995 pct) ingots with the following chemical composition:

| ZUSAMMENSETZUNG IN % PCT | |||||||

| KLASSIFIZIERUNG DES TYPS | NENNGEHALT AN ZINK | 1 PB MAX | 2 CD MAX | 3 FE MAX | 4 SN MAX | 5 CU MAX | 6 AL MAX |

| SHG ZINK | 99,995 | 0,003 | 0,001 | 0,002 | 0,002 | 0,003 | 0,001 |

The material is supplied

in ingot packages of approx. 1.0 tn,

the individual ingot weighing

approx. 20 kg

Aluminium ingots

We purchase 99.8% aluminium ingots with the following chemical composition:

| ZUSAMMENSETZUNG IN % PCT | |||||||

| KLASSIFIZIERUNG DES TYPS | NENNGEHALT AN ALIMINIUM | 1 PB MAX | 2 CD MAX | 3 FE MAX | 4 SN MAX | 5 CU MAX | 6 AL MAX |

| ALUMINIUM INGOTS | 99,995 | 0,003 | 0,001 | 0,002 | 0,002 | 0,003 | 0,001 |

The material is supplied in ingot packages of approx. 1.0 tn, the individual ingot weighing approx. 20 kg

Hyper-pure magnesium ingots

We purchase 99.95 magnesium ingots with the following chemical composition:

| ZUSAMMENSETZUNG IN % PCT | |||||||

| KLASSIFIZIERUNG DES TYPS | NENNGEHALT AN MAGNESIUM | 1 PB MAX | 2 CD MAX | 3 FE MAX | 4 SN MAX | 5 CU MAX | 6 AL MAX |

| MAGNESIUM INGOTS | 99,995 | 0,003 | 0,001 | 0,002 | 0,002 | 0,003 | 0,001 |

The material is supplied in ingots weighing 30 g and of 12 cm size

Our products

The Foundry produces all types of zamak required by the market, using hyper-pure materials, by-products and new production scrap, added in varying proportions to the melting bath according to the customer’s specific needs. Authoritative studies and statistics show that the environmental impact of recovery of these materials sent for melting is twenty times lower than the extraction from ore and subsequent treatment.